LIGHTWEIGHT

NOISE DAMPENING

RAIN RESISTANT

HEAT RESISTANT

WIND RESISTANT

FIRE RESISTANT

SEA AIR RESISTANT

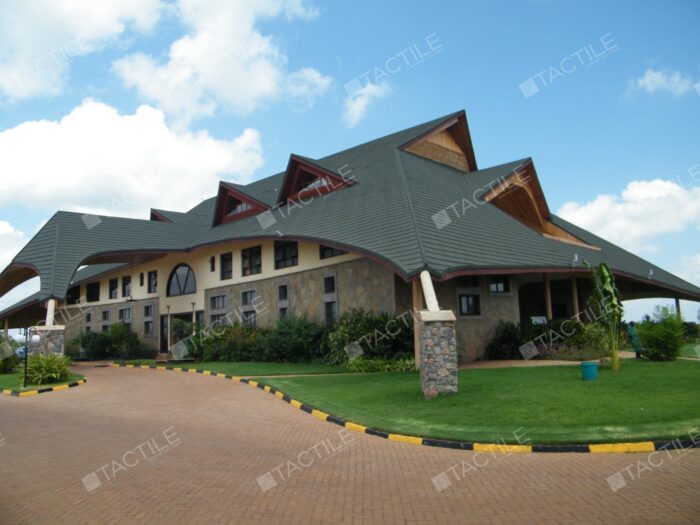

DURABLE & STRONG

ECO-FRIENDLY & RECYCLABLE

AVAILABLE FOR EXPORT

EASY TO INSTALL

SPEEDY CONSTRUCTION

COST SAVING DESIGN

50 YEAR WARRANTY